This is the first in a series of articles that looks at the Manufacturing module in Jiwa 7.

Overview

A Bill of Material also referred to as a Bill or BOM is a template or formula used to make a finished product or component that goes into the manufacture of another product.

In this article we look at the Bill of Materials form and how to create simple Bills.

Advanced functions and features are covered in separate articles this includes;

- Production Areas and Lines,

- Work centres, and

- Sub-assemblies

Before we begin let’s have a look at some of the manufacturing terms used in Jiwa.

| Term | Description |

| Production areas | Dedicated area in a warehouse/factory where an item is manufactured.

For example if you manufacture doors and windows your warehouse/factory may have separate areas where each is manufactured, like

|

| Production line | Production lines contained within a production area. If we use the door and window example the Door and Frame Production area may have the following production lines;

|

| Work Centre | Processes or task associated with a production line. If we use the Door example the Sliding Doors production line may have the following work centres,

|

| Stage | Stages represent the steps in your manufacturing process and can be as simple or as complex as required. Each stage can have it’s own components (inputs) that go into the manufacture of one or more outputs.

Taking our door manufacturing process the bill of material may have the following stages;

At least one stage needs to be setup in a Bill of Material |

| Sub Assembly | A bill of material to create a component that is used in the manufacture of another component or a finished product. |

| Inputs | Components that go into the manufacture of another product |

| Outputs | The item that is produced at the end of the manufacturing process this can be a finished product or another component that is used to manufacture another product |

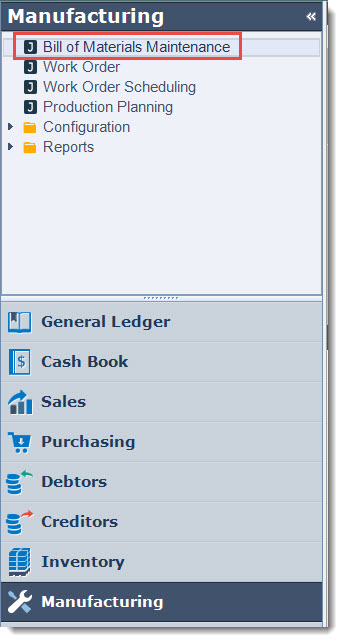

From the menu select Manufacturing | Bill of Materials Maintenance